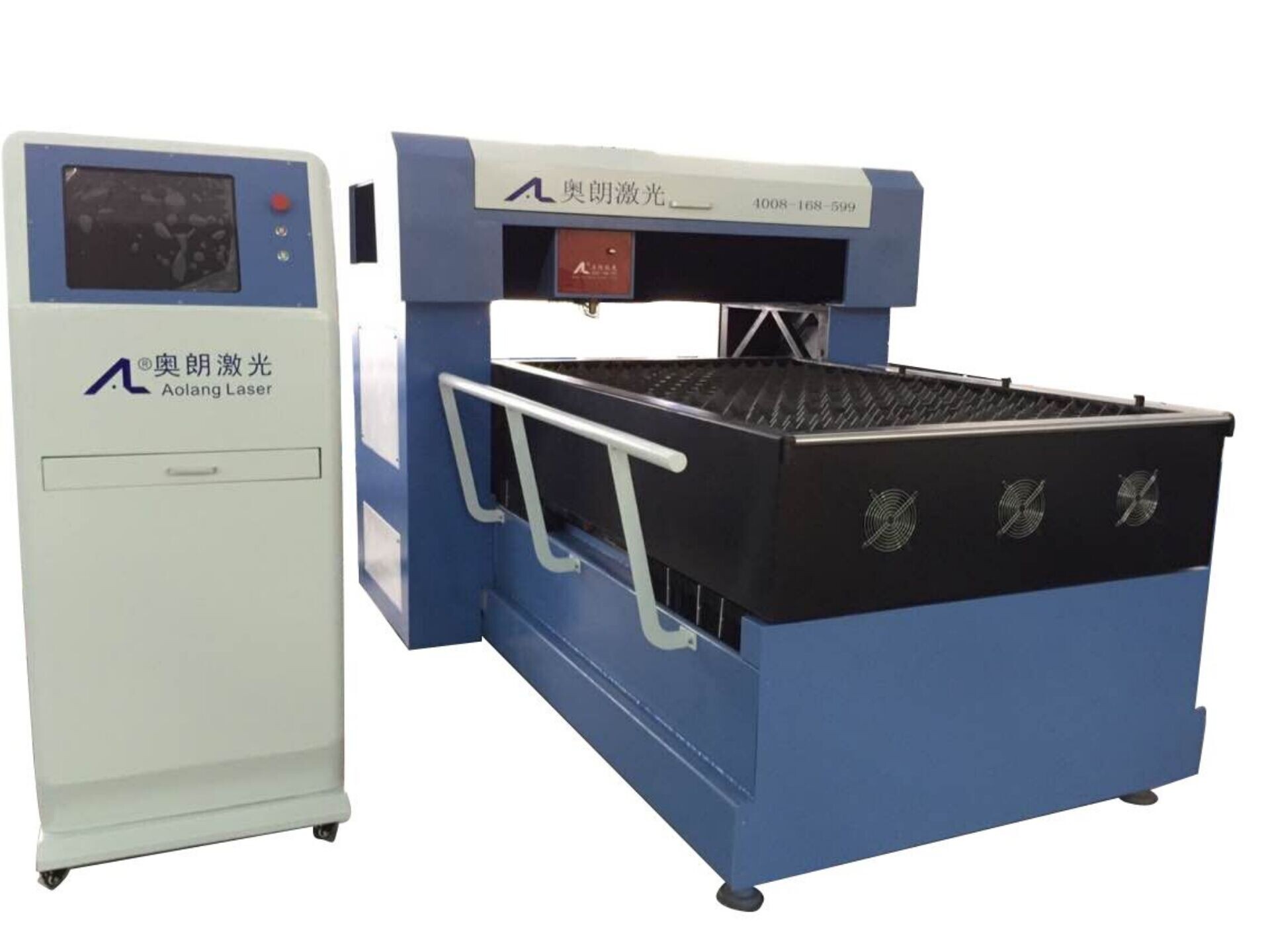

AL-CO2大功率激光切割机

奥朗激光多样化的产品广泛应用于现代工业——彩盒、电子、轻工等各类模切板加工;碳钢、不锈钢、铝合金等金属薄板的切割 加工;亚克力、塑胶、复合材料等各类非金属中厚板材的切割加工。

AL-CO2-1000W-1500W型激光切割机是为钢板及各种重型板材切割加工行业量身定做的。稳定的机身设计、灵活的执行机构、配套的激光切 割专用软件,使加工手段游刃有余,其效率和质量远胜于传统的切割方法,可24小时不间断工作,使AL-CO2-1000-1500W型成为用户钢板切割的加工利器。

奥朗激光的精良产品拥有极好的性能价格比,助你在同行竞争中轻松应付

我们的产品总有一款如同为您度身定制。我们是您身边的激光应用的专家朋友,您事业拓展的合作伙伴。

【独特优点】 AL-CO2-1000W-1500W 型数控技术激光切割机组采用“混合光路”的原理进行设计制造,数控激光切割机床工作台的运行方式为单向滑台式,

既减小了机床设备的占地空间,增加了切割加工过程中的运动稳定性和可靠性,又减小了切割功率受光程远近的影响,确保切割缝隙均匀一致,校光及维护保养便利。

AL-CO2-1000W-1500W型数控技术激光切割机配置了性能优良的轴快流二氧化碳激光器,激光器输出激光束,经外光路系统处理及传输,再经切割头聚焦,并吹以辅助切割气体,在数控机床精密驱动下,实现对各种金属以及非金属板材的激光切割加工。

* AL-CO2-1000W-1500W型数控技术激光切割机的控制软件运行在Windows操作系统上,具有CAD/CAM自动编程及优化排样套裁功能,可识别多种CAD图形文件。为方便使用,客户还可在系统中建立自己的激光切割工艺数据库,使用时可直接从工艺数据库中选取适宜的工艺方案。

* AL-CO2-1000W-1500W型数控激光切割机的关键器件如CNC数控系统、交流伺服电机及其驱动器、精密滚动直线导轨、精密滚珠螺杆、光学镜片等均采用原装进口,以保证设备的可靠和稳定。

* AL-CO2-1000W-1500W型数控激光切割机组还配有双温冷却水机组,还可选配稳压电源、无油空气压缩机及冷却干燥机、抽烟吸尘装置等辅助设备,以确保机组的正常运行。

【机型特点】

* 混合光路设计,单向滑台方式的运动方式有利运动系统的稳定可靠,切割端面更光洁,精度更高,激光加工质量稳定,适用于对激光切割端面有严格要求的应用。

* 钢结构底座,经长达9个月以上的退火、自然时效、人工时效、振动时效等多重去应力处理,确保机床底座结构稳定可靠。

* 气缸式夹钳,夹紧可靠,保证零件加工精度。

* 采用进口伺服电机、精密滚珠丝杆驱动,定位精确,曲线加工高精度,速度快。

* 丝杆及导轨采用全封闭式防护,减少粉尘的污染,提高了传动件的使用寿命,大大减小日常维护。

* 机床导光系统采用封闭式光路,抽屉快换式镜座,确保镜片的洁净与寿命。

* 采用ⅡⅥ公司高品质光学镜片组,并具备多焦距5”及7.5”聚焦镜快速更换功能。

* 激光切割头配有全自动高度跟踪系统,加工时激光焦点高度保持严格一致,反应灵敏、准确,保证切割质量。

* 激光切割头可承受2.0Mpa气体压力,适用于各种板材的切割,结构简单,调整方便。

* 采用国际高品质的我公司自主开发的数控系统,集成气路控制系统及所有的气动、传动元件全套进口,设计先进。

* CNC电气控制操纵台可随意移动,高度适中,操作方便。

* 精密数控机床,高刚性框架结构机身,具有良好的整体刚性、稳定性及动态性能;

* X、Y、Z三轴均采用日本三菱、松下等伺服电机驱动,性能好、响应快、免维护;

* 选用日本、韩国著名品牌的精密滚珠螺杆传递动力,精密滚动直线导轨导向及承载,确保机床的运行精确无误;

* 切割头正压吹气干燥除尘装置,保护镜片喷嘴不受烟尘污染以及低温结霜;

* 切割头自动跟踪调校与工件间的间距,维持固定的焦距以提升切割质量;

* 专门设置的抽风吸尘装置,维护作业环境免受烟尘污染。

【数控系统】

* 高稳定性的标准工控机配置、USB接口、快速模拟量输入输出、快速数字量输入输出模块、外围设施的运行均由PLC逻辑控制。

* Windows视窗操作系统、我公司自主开发的激光机床专用CNC数控系统、激光功率控制、Z轴自动跟踪执行等控

制软件,方便实现直线插补、圆弧插补、拟合、反向间隙补偿、丝杆螺距误差补偿、割缝补偿等众多功能。

* MCP机床控制面板、17”大屏幕的人机对话、标准键盘及鼠标作业、图形并中/英文界面方便操作。

【切割软件】

* 构筑于AotoCad平台的配套的激光切割加工专用编程软件(AcadRcam)优化套排,人机交流互动,方便用户在AotoCad设计图平台上对绘制的图形进行入库、套排、路径优化、路径顺序、切割方向、切割起点等各种激光加工的工艺细节及方案处理。

* 内置切割专家数据系统,切割时可以自动或手动调用这些参数;还可根据经验建立客户自已的常用激光切割工艺数据库,操作时直接从中选取适宜的工艺方案。

AL - high power CO2 laser cutting machine

AOLang Laser diversified products are widely used in modern industry, color box, electronics, light industry and other kinds of die cutting plate processing; Such as carbon steel, stainless steel, aluminum alloy sheet metal cutting processing; Acrylic, plastic, composite materials and other kinds of non-metallic medium thickness plate cutting processing.

AL - 1000 w - 1000 w CO2 laser cutting machine for steel plate and various kinds of tailor-made heavy plate cutting processing industry. Stable airframe design, flexible actuator, form a complete set of laser cutting cut proprietary software, and the processing method, the efficiency and quality is far better than the traditional method of cutting, can work 24 hours a day, make the AL - CO2-1000-1500 - w be users of steel plate cutting processing technique.

AOLang Laser excellent products with excellent price performance ratio, help you easily cope with in the peer competition

Our products always have a like a tailor-made for you. We are laser application expert friends around you, your business partner.

AL - unique advantages 】 【 - 1000 w - 1500 w CO2 laser cutting machine of numerical control technology adopts the principle of "hybrid optical path" to carry on the design and manufacture, CNC laser cutting machine table operation mode for unidirectional sliding table,

Reduced the machine tool equipment covers an area of space, increase the movement stability and reliability in the cutting process, and reduces the cutting power is affected by light cjay nearly, ensure cutting gap uniformity, the school light and convenient maintenance.

AL - - 1000 w - 1000 w CO2 laser cutting machine of numerical control technology is configured with excellent performance of shaft fast flow CO2 laser, laser output beam, processing and transmission by the optical path of foreign trade system, then through cutting head focus, and cutting gas, blow to aid in the numerical control machine tool precision, driven by implementation of laser cutting and processing of various kinds of sheet metal and nonmetal.

* AL - - 1000 w - 1000 w CO2 laser cutting machine of numerical control technology in the control software running on Windows operating system, with CAD/CAM automatic programming and optimal layout suit cut function, and can identify various CAD graphics file. For ease of use, customers can also set up their own laser cutting technology in the system database, can be directly from the selection of process database when using appropriate processing plan.

* AL - CO2-1000 w - 1500 - w CNC laser cutting machine of key parts such as CNC numerical control system, ac servo motor and its drive, precision linear rolling guide rail, precision ball screw, optical lens, adopt imported, to ensure that the equipment is reliable and stable.

* AL - CO2-1000 w - 1500 - w CNC laser cutting machine is also equipped with dual temperature cooling water unit, also optional regulated power supply, oil free air compressor and cooling dry machine, smoke dust collection device and other auxiliary equipment, to ensure the normal operation of the unit.

【 model features 】

* hybrid optical path design, the one-way slide ways favorable motor system is stable and reliable, cutting face more bright and clean, higher precision, laser processing quality is stable and suitable for laser cutting face has strict requirements.

* steel base, after more than nine months of annealing, natural aging and artificial aging, vibration aging, such as multiple to deal with the stress, ensure the machine base structure is stable and reliable.

* cylinder type clamp, reliable clamping, ensure parts processing precision.

* imported servo motor, precision ball screw drive, precision positioning, curve machining high precision, fast speed.

* lead screw and guide rail with fully enclosed protection, reduce dust pollution, improve the service life of the transmission parts, greatly reducing the daily maintenance.

* machine system adopts closed optical path of light transmission, quick change drawer type lens, to ensure that the lens is clean and life.

* use Ⅱ Ⅵ company high-quality optical lens group, and have more focus lens focal length 5 "and 7.5" quick change function.

* laser cutting head is equipped with automatic tracking system, processing laser focus strictly consistent altitude, responsive and accurate, and ensure the cutting quality.

* laser cutting head can be 2.0 Mpa gas under pressure, suitable for cutting all kinds of plank, simple structure, easy to adjust.

* USES the international high quality of my company independent development of numerical control system, integrated all the pneumatic, pneumatic control system and a full set of imported transmission component, is advanced in designing.

* CNC electric control console can move, medium height, easy to operate.

* precision CNC machine tools, high rigid frame structure body, has a good overall rigidity, stability and dynamic performance;

* X, Y and Z axis adopts Japan's mitsubishi, panasonic servo motor driver, good performance, fast response, free maintenance;

* choose Japan, South Korea famous brand of precision ball screw transmission power, precision linear rolling guide bearing, guide and ensure the operation of the machine tool precision;

* cutting head positive pressure air blow dry dust removal device, protect the lens nozzle from soot pollution, and low temperature frost;

* automatic tracking the cutting head set-up and spacing between workpiece and maintain fixed focal length in order to enhance cutting quality;

* dedicated convulsions suction device, maintenance work environment from smoke and dust pollution.

【Numerical control system】

* high stability of the standard industrial control configuration, USB interface, fast analog input and output, fast digital quantity input/output module and the operation of the peripheral facilities are controlled by the PLC logic.

* Windows operating system, I own development company dedicated CNC laser machine tool numerical control system, automatic laser power control, the Z axis tracking control execution, etc

System software, easy to realize linear interpolation, arc interpolation, fitting, backlash compensation, screw pitch error compensation, slotting compensation, and many other functions.

* MCP machine control panel, 17 "screen man-machine dialogue, the standard keyboard and mouse operation, graphics, and Chinese/English interface and convenient operation.

【cutting software】

* platform in AotoCad in the form a complete set of laser cutting machining programming software (AcadRcam) optimization set of row, human-computer interaction, convenient user on AotoCad design platform for drawing graphics library, the path of set of row, optimization, order and cutting direction, cutting starting point, technical details and solution for all kinds of laser machining processing.

* built-in cutting expert data system, cutting can be automatically or manually invoked when these parameters; Can also according to the experience of building customer own database commonly used laser cutting technology, operation directly choose the appropriate process. |